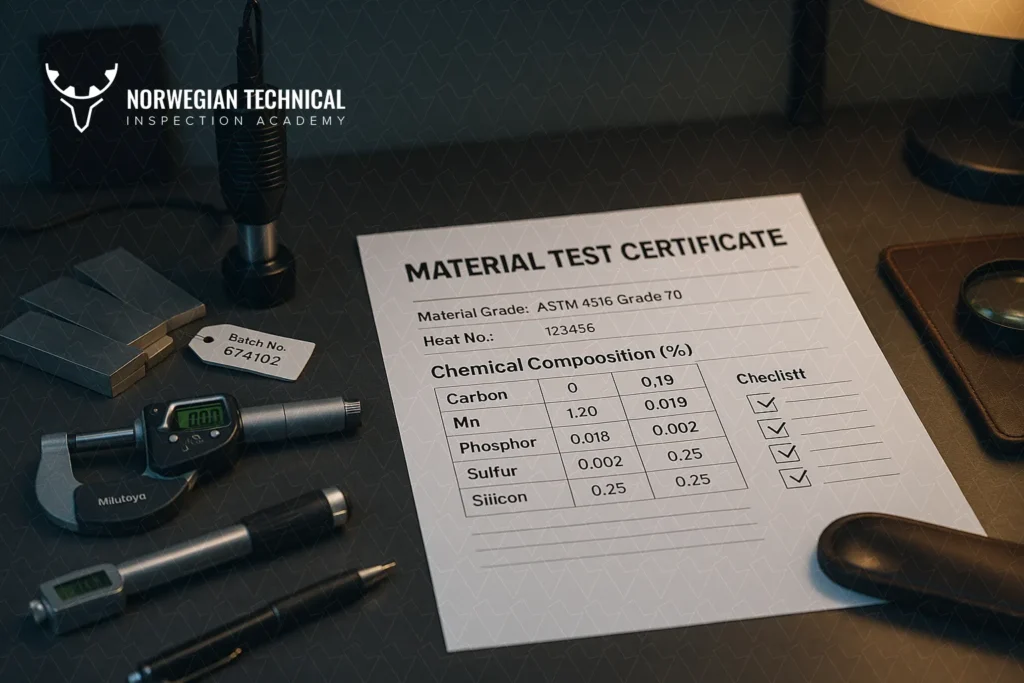

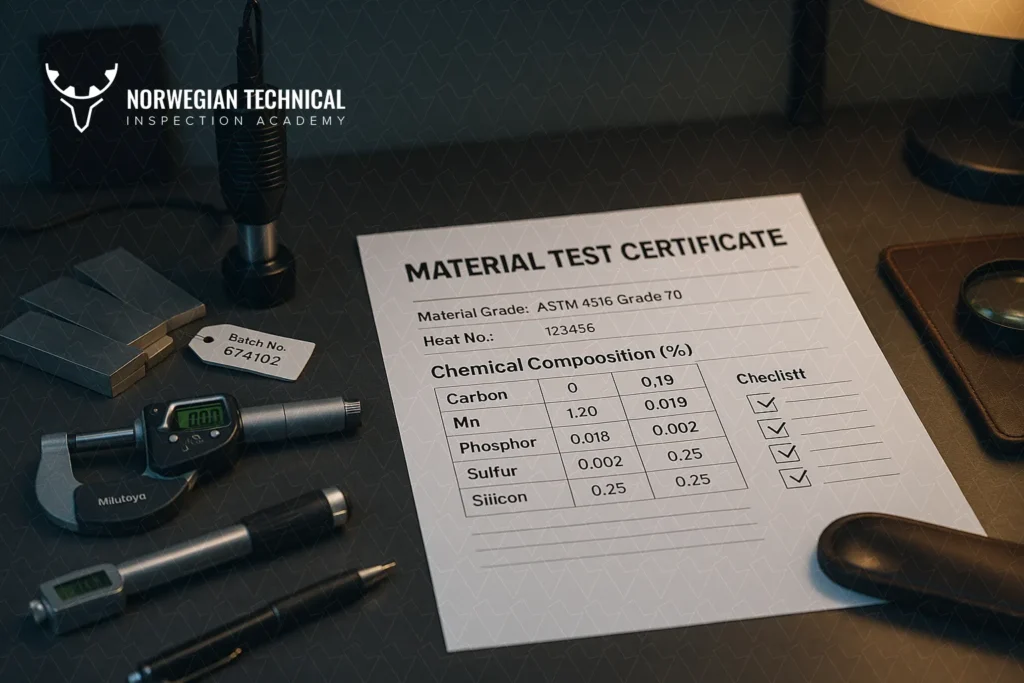

A Material Test Certificate (MTC) is the manufacturer’s documented evidence that delivered material conforms to the purchase order and the standards referenced by the project spec. Interpreting an MTC means verifying PO and item match, heat numbers, test results, signatories (e.g., EN 10204 3.1/3.2), and traceability into your vendor dossier—without inventing criteria.

New to raw material inspection? Start with the structured course: Raw Material Inspection Training.

An MTC (Material/Mill Test Certificate) states conformity to the order and shows the test results required by your project spec. It is the anchor for traceability (heat → lot → piece), acceptance “as per” the referenced standard/edition, and release. A clean MTC saves time at receiving, FAT, and final dossier close-out.

Typical applies-to: plates, bars, forgings, castings, and material used in valves, pressure parts, and fabricated items.

Need the full comparison and when to specify 3.2? See EN 10204 3.1 vs 3.2: Differences Explained.

Read top-to-bottom; confirm identity, scope, and evidence before the numbers.

Acceptance phrasing you’ll reuse: “Accepted as per <standard/edition> referenced by the project spec.” Do not restate numeric limits inside your report unless your spec explicitly requires them.

Use this checklist to approve Material Test Certificates (MTCs) against your PO and the standards/edition referenced by the project spec. If you’re new to the process, the structured hub is the Raw Material Inspection Training.

| Item | What to verify | Evidence to capture | Acceptance reference (wording) | Status |

| PO & item match | PO number/line, customer, project, delivery quantity | PO copy; delivery note; packing list | “Accepted as per order/project spec.” | ☐ |

| Product identity | Form/grade/size match the order | Datasheet/drawing refs; mill description | “Accepted as per order & drawing.” | ☐ |

| Heat/batch numbers | Heats on MTC appear on delivered items | Photo of heat stamps/tags; receiving IR | “Traceable heat → items per spec.” | ☐ |

| Certificate type | EN 10204 3.1 or 3.2 as ordered | 3.1: manufacturer sign; 3.2: + buyer/official body | “Type per PO/ITP.” | ☐ |

| Test results present | Chemical, mechanical, impact/hardness, NDE (if applicable) | MTC pages; annex list | “Results as per standard/edition referenced.” | ☐ |

| Standard & edition | Methods cite the correct standard/year | Marked clauses/editions on MTC | “Edition as per project spec.” | ☐ |

| Lab & calibration | Lab identity/accreditation; instrument calibration linkage | Lab note; calibration refs (IDs/dates) | “Lab/cal per procedure.” | ☐ |

| Document control | Cert ID/rev, date, pages, attachments | Front page; attachment table | “Controlled per supplier procedure.” | ☐ |

| Corrections | No hand edits; revisions reissued | Versioned reissue if any change | “Reissued per doc control.” | ☐ |

| Attachments list | Annexes exist and are included | Attachment table ticked | “Complete per annex list.” | ☐ |

| Traceability map | Heat → lot → piece/tag mapping | Heat map table (see below) | “Mapped to tag/serial.” | ☐ |

| Dossier indexing | MTCs filed and cross-referenced | Dossier index row created | “Filed per dossier index.” | ☐ |

| Acceptance line | Your conclusion uses correct phrasing | IR note with clause/edition | “Accepted as per <standard/edition> referenced by the project spec.” | ☐ |

Need a refresher on certificate types? See EN 10204 3.1 vs 3.2: Differences Explained.

| Field | Value |

| PO & item match | |

| Product identity (form/grade/size) | |

| Heat/batch numbers | |

| Certificate type (3.1/3.2) | |

| Test results present | |

| Standard & edition | |

| Lab & calibration | |

| Doc control (ID/rev/date/pages) | |

| Corrections/reissue | |

| Attachments list | |

| Traceability map linked | |

| Dossier indexed | |

| Acceptance (as per <standard/edition>) |

Keep this table in your receiving IR and final dossier. Every record must tie to a single tag/serial.

| Heat / Batch No. | Product form & grade | Size / Spec note | Qty received | Piece / Tag / Serial | MTC Ref (ID / page) | Delivery Note | IR Ref | Status |

| H12345 | Plate S*** | 12 | TAG-P001…P012 | MTC-001 / pp.1–3 | DN-045 | IR-RCP-021 | ☐ | |

| H67890 | Forging A*** | 4 | TAG-F201…F204 | MTC-002 / pp.1–2 | DN-046 | IR-RCP-022 | ☐ |

| Field | Value |

| Heat / Batch No. | |

| Product form & grade | |

| Size / Spec note | |

| Quantity received | |

| Piece / Tag / Serial | |

| MTC Ref (ID / page) | |

| Delivery Note | |

| IR Reference | |

| Status | ☐ Conform ☐ NCR |

Photo & file naming (keeps audits painless)

ITP integration (one line to paste)

“Receiving — Hold (H): Verify MTC type (EN 10204 3.1/3.2) and heat mapping. Acceptance as per <standard/edition> referenced by the project spec. Records: MTC, heat map, photos, IR.”

Planning inspection points across your PO? Use the cross-pillar template once: Vendor Inspection ITP Template.

| Red flag | Why it’s risky | What to do (keep acceptance phrasing) |

| PO / item mismatch | Wrong material could be accepted | Request a corrected MTC that matches PO/line/drawing; re-index in dossier. |

| Heat numbers don’t match delivered items | Breaks traceability | Re-map heat → lot → piece/tag; fix labels; attach updated heat map to IR. |

| Certificate type wrong (3.1 ordered, 3.2 needed) | Non-compliance to order/ITP | Obtain 3.2 with proper signatures/witness notes as per PO/ITP; do not accept ad-hoc upgrades without buyer approval. |

| Missing signatures/stamps (3.2) | Independence not demonstrated | Have the buyer’s inspector and/or officially designated body sign as ordered or reissue the certificate. |

| Partial test results / wrong standard edition | Acceptance basis unclear | Re-test or re-document as per the standard/edition referenced by the project spec; attach method references. |

| Handwritten edits on a signed MTC | Document control compromised | Reject edits; request re-issued, version-controlled MTC; cite doc control procedure. |

| Lab accreditation/calibration is missing | Evidence credibility weak | Add lab accreditation or calibration references per procedure; list instrument IDs and expiry. |

| Mixed heats in one line | Ambiguous mapping | Split MTC lines per heat; update packing/delivery and tag list accordingly. |

Rule: never invent numeric limits. Your acceptance line should read: “Accepted as per <standard/edition> referenced by the project spec.”

1) What is an MTC?

A Material (Mill) Test Certificate evidence conformity to the purchase order and lists required test results, with acceptance applied as per the standard/edition referenced by the project spec.

2) Which standard defines certificate types?

EN 10204 (e.g., 3.1, 3.2) defines inspection certificate types and signatory expectations.

3) What’s the difference between 3.1 and 3.2?

3.1 is signed by the manufacturer’s authorized inspection representative. 3.2 adds independent validation by the buyer’s inspector and/or an officially designated body, as ordered.

4) Do labs need accreditation?

Follow your project procedure. If accreditation is required, reference it on the MTC and attach evidence; instruments used should have valid calibration.

5) Can one MTC cover multiple heats?

Yes, if each heat is separately listed and traceable. Prefer one line per heat and a clear heat→piece/tag map.

6) What if the MTC cites the wrong edition?

Ask for re-documentation or re-test as per the correct edition referenced by the project spec. Note changes in the dossier index.

7) How long should we keep MTCs?

Follow contract/regulatory retention. File MTCs in the final dossier, cross-referenced to delivery notes and tag/serials.

8) Where can I see 3.1 vs 3.2 examples?

See EN 10204 3.1 vs 3.2: Differences Explained for signatory roles and use cases.

Filename: MTC_Receiving_Checklist.pdf

CTA: Download the MTC Receiving & Verification Checklist (PDF) and use it at your next receiving inspection.

Build a repeatable receiving workflow for EN 10204 certificates and MTCs, with risk-based checks and traceability that survives audits. Join Raw Material Inspection Training — practical labs, acceptance language, and dossier assembly aligned to what your projects reference.

At NTIA (Norwegian Technical Inspection Academy), we specialize in delivering world-class training programs in vendor inspection, quality surveillance, and technical compliance – specifically tailored for professionals in the oil, gas, and energy industries.

Copyright © 2025 by NTIA. All Rights Reserved.