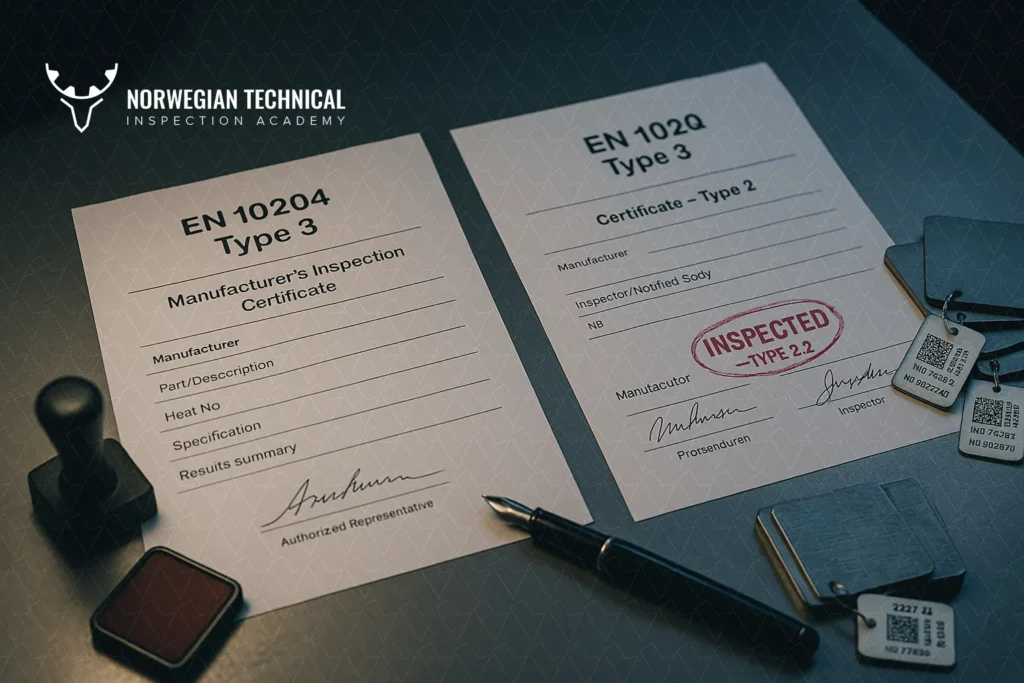

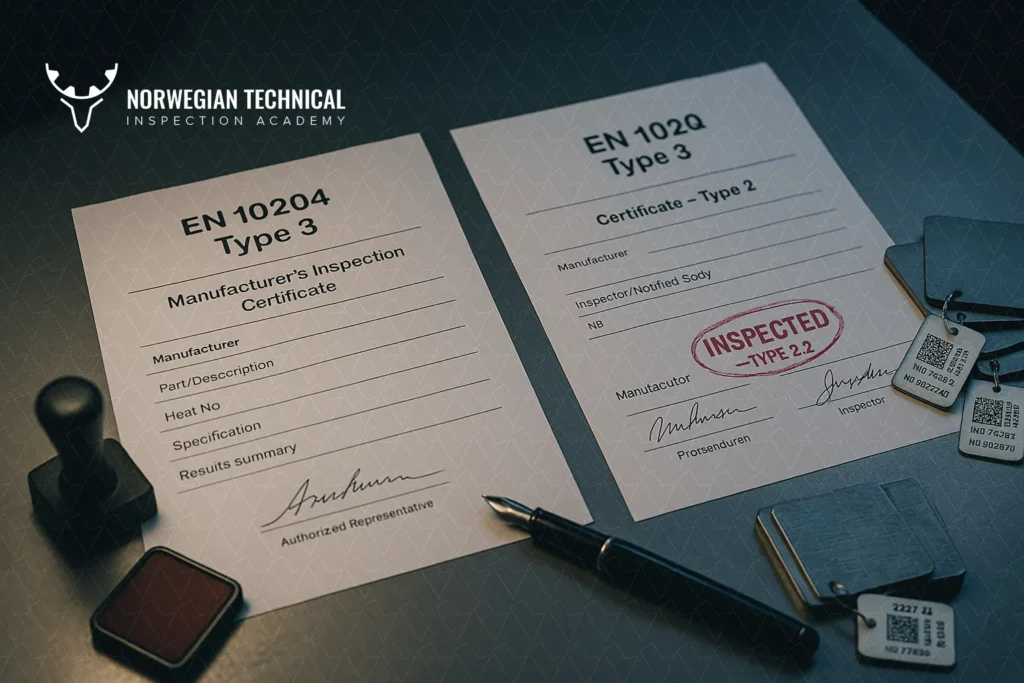

EN 10204 defines inspection certificates for metallic products. A 3.1 certificate is issued by the manufacturer’s authorized inspection representative with heat/batch test results and a statement of conformity. A 3.2 certificate adds independent validation by the buyer’s inspector and/or an officially designated body, when required by the PO/project spec—no ad-hoc values.

New to materials & MTCs? Start with the structured course: Raw Material Inspection Training. For hands-on certificate reading, see the MTC Interpretation Guide.

What you’ll get in this guide:

EN10204 covers metallic material such as plates, bars, forgings, and castings.

3.1 certificate (manufacturer-issued)

3.2 certificate (with independent validation)

| Topic | EN 10204 3.1 | EN 10204 3.2 |

| Signatory | Manufacturer’s authorized inspection representative | Manufacturer + buyer’s inspector and/or officially designated body |

| Independence | Internal | External/official participation |

| Evidence | Heat/batch test results; conformity to order | Same results with independent validation/witness (as ordered) |

| Typical use | Standard criticality, proven mill/vendor | High-risk service, regulatory/authority or client requirement |

| Cost/lead time | Lower | Higher (coordination, witnessing, stamps) |

| Acceptance | Per PO/project spec & referenced standards | Per PO/project spec & referenced standards |

Practical rule: don’t try to “upgrade” a 3.1 to 3.2 after the fact. Define the required type in the PO/ITP from day one.

| Item | What to verify | Result |

| PO & item match | PO number, line item, product form/grade, quantity align with delivery | ☐ |

| Heat numbers | Heat/batch numbers present and traceable to delivered items | ☐ |

| Test results present | Chemical, mechanical, impact/hardness, NDE (if applicable) included as required by the project | ☐ |

| Standard references | Procedures/tests cite the correct standard & edition (per project spec) | ☐ |

| Signatures/stamps | 3.1: manufacturer’s authorized rep signed. 3.2: manufacturer + buyer’s inspector and/or official body signed (as ordered) | ☐ |

| Lab & calibration | Test lab identity and calibration/competence referenced per project procedure | ☐ |

| Traceability map | Certificate lines link to delivery note and item/tag/serial list | ☐ |

| Corrections | Any corrections are controlled (reissue/versioning), not hand-amended | ☐ |

| Acceptance phrasing | “Accepted as per <standard/edition> referenced by the project spec.” No ad-hoc values | ☐ |

Rolling this into your ITP? Add a W/H point for certificate review and reference it in the FAT/receiving stage: Vendor Inspection ITP Template.

What must be on an EN 10204 certificate (3.1 or 3.2):

How to maintain traceability (simple and defensible):

| Red flag | Why it matters | Fix (acceptance phrasing preserved) |

| Heat numbers on MTC don’t match delivery/tags | Breaks traceability | Request corrected MTC; re-map heat → items; update dossier index. |

| Missing 3.2 signatory/stamp when ordered | Certificate type not satisfied | Have buyer’s inspector/official body sign as per order/ITP or reissue certificate. |

| Partial test results or wrong edition cited | Acceptance basis unclear | Re-test or re-document as per the standard/edition referenced by the project spec. |

| Handwritten edits on a signed MTC | Document control at risk | Reject edits; request reissued certificate with proper revision history. |

| Lab identity/calibration not referenced | Evidence credibility weak | Add lab accreditation/calibration references per project procedure; attach certs. |

| Mixed heats on one line item | Ambiguous mapping | Split MTC lines per heat/batch; update packing/delivery and tag list. |

Rule: do not invent numeric limits. Always write: “Accepted as per <standard/edition> referenced by the project spec.”

What is EN 10204?

A standard that defines inspection certificate types for metallic products. Certificates declare conformity to the order and list test results required by the project spec.

What’s the difference between 3.1 and 3.2?

3.1 is issued by the manufacturer’s authorized inspection representative. 3.2 adds independent validation by the buyer’s inspector and/or an officially designated body, as required by the order.

Who can sign a 3.2 certificate?

The manufacturer plus the buyer’s authorized inspector and/or an officially designated body—exact signatories follow the PO/ITP.

Is 3.2 always required?

No. Use 3.2 when the project spec demands third-party/official oversight or the risk profile/regulations justify it.

Can a 3.1 be “upgraded” to 3.2 later?

Not without the buyer’s written approval and proper witnessing/signature as per the order/ITP. Define the required type at PO placement.

What must appear on a Material Test Certificate (MTC)?

PO, item, product details, heat numbers, test results, referenced standards/editions, signatures/stamps, and controlled revision/attachments.

How should I file certificates in the vendor dossier?

Map heat → items → tag/serials, store MTCs with delivery/packing, and list them in the dossier index. Acceptance wording stays as per the standard/edition referenced.

Filename: EN10204_3.1_vs_3.2_Checklist.pdf

CTA: Download the 3.1 vs 3.2 Verification Checklist (PDF) and use it on your next receiving inspection.

Build a repeatable receiving & approval workflow for MTCs and EN 10204 certificates. Join Raw Material Inspection Training — risk-based checks, traceability mapping, and acceptance phrasing as per the standards your projects reference.

Deep-dive on reading certificates: MTC Interpretation Guide

Plan how certificates show up in inspection points: Vendor Inspection ITP Template

At NTIA (Norwegian Technical Inspection Academy), we specialize in delivering world-class training programs in vendor inspection, quality surveillance, and technical compliance – specifically tailored for professionals in the oil, gas, and energy industries.

Copyright © 2025 by NTIA. All Rights Reserved.