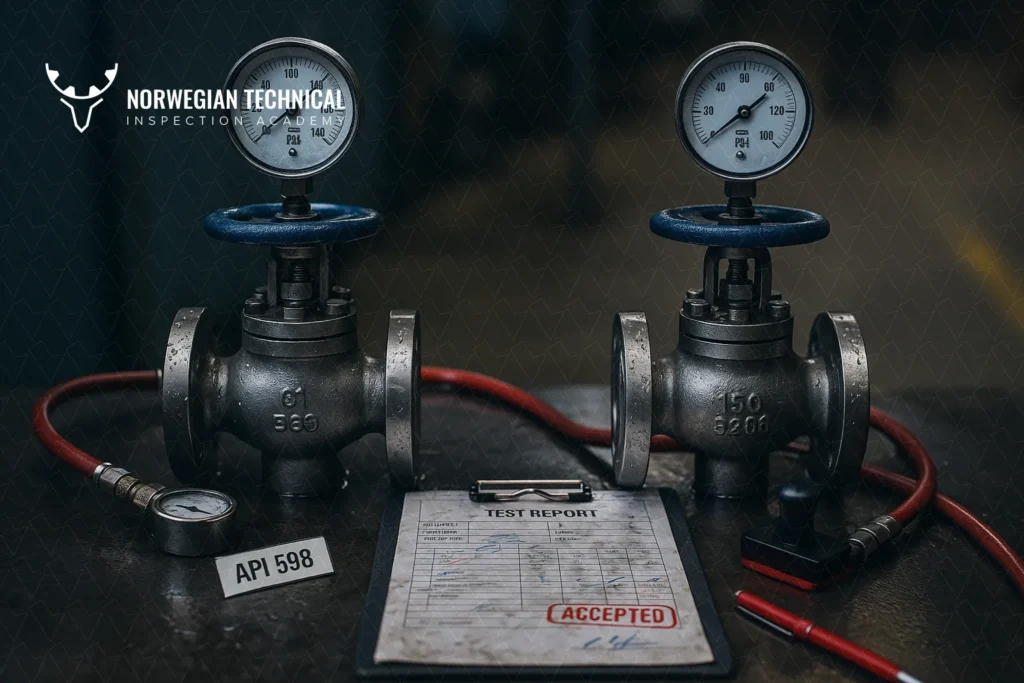

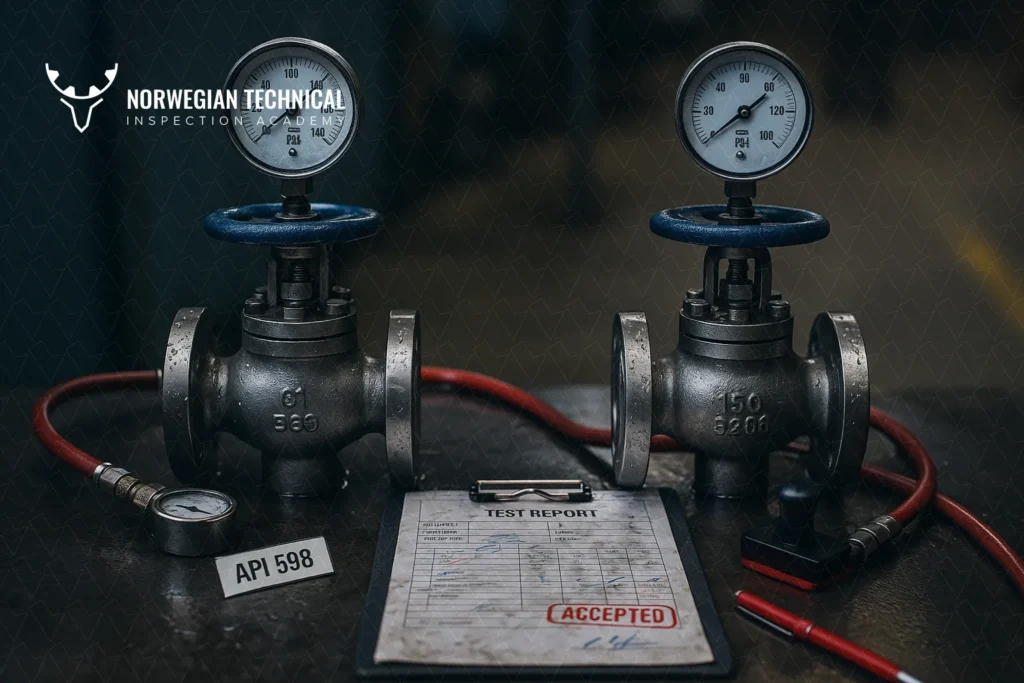

This guide helps you understand the practical differences between API 598 and ISO 5208, and how each flows into your ITPs, vendor dossiers, and acceptance reporting (see [Vendor Inspection basics] (W1.1)).

📌 Last updated: September 2025 — References: API 598 (2023), ISO 5208 (2015), EN 12266-1 (2012), ANSI/FCI 70-2 (2021).

📂 Downloads: [Comparative Acceptance Table (PDF)] • [Seat/Hydro Test Form (Excel)]

Philosophy

Scope of Tests

Control Valves

Both standards defer to ANSI/FCI 70-2 for control valve seat tightness (e.g., Class VI). This route must be documented per tag in your ITP (use the [Vendor Inspection ITP Template] (W1.4)).

Regional Alignment

Documentation

Quick Pick

📌 If tight acceptance is driven by chronic failure mechanisms, consult [Valve Failure Modes] (W3.4) to understand real-world failure patterns before fixing criteria.

API 598. Shell/closure/backseat pressures and minimum hold times are tabled by edition; medium is typically water (air/gas by agreement and safety). Backseat is tested only if the design includes it—validate preconditions with your checklist.

ISO 5208. For seat tests you must declare the Class (A–G), the test medium, and the measurement units (e.g., bubbles/min for gas, mL/min for liquid). The form records the measured value against the class limit—see sequencing guidance in Hydrostatic vs Seat procedures.

EN 12266-1. EU-centric route often used alongside or instead of ISO 5208; cite it explicitly when the spec is EN-based, and lock the reference in your ITP.

Engineer’s tip: High-containment or SIL-relevant services → API 598 or tight ISO Classes A/B. Moderate services → ISO mid-classes C–E after risk review; reflect the decision in the ITP.

ANSI/FCI 70-2 is the authoritative leakage test for control valves (incl. Class VI for very tight shutoff). In mixed packages, route on/off valves to API/ISO and controls to FCI 70-2; document per tag in the ITP and close evidence in the dossier.

Always lock the edition, state medium/pressure/hold, and for ISO, Class + units (the ITP template helps enforce this consistently).

Mini examples.

Use a structured form: Tag, NPS/DN, Class/Rating, Material, Standard+Edition, Medium, Pressure, Hold, Temp, Seat direction, Measured leakage + units, Instrument IDs & cals, Operator/Witness. Standardize this across vendors with the [Master Inspection Templates Pack] (W2.5).

Frequent errors (+ quick fixes).

1) Is API 598 stricter than ISO 5208 for seat leakage?

API 598 is typically go/no-go; ISO 5208 is graded—tight A/B classes can approach near-zero when specified.

2) Which standard covers “Class VI” tight shutoff?

ANSI/FCI 70-2 (control valves). Do not use API 598/ISO 5208 for control-valve leakage classes.

3) Do I need both API 598 and ISO 5208 on the same valve?

Generally, no—choose one route per on/off valve; control valves → FCI 70-2. Mixed packages can be assigned per tag in the ITP.

4) Where does EN 12266-1 fit vs ISO 5208?

It’s the EU testing framework broadly aligned with ISO 5208; use it when the project specification is EN-centric.

5) What must be on the acceptance record to avoid disputes?

Standard + Edition, medium/pressure/hold, and for ISO 5208 the Class + units; attach calibration evidence and photos.

6) When is a backseat test required?

Under API 598, only if the valve has a backseat feature (e.g., gate/globe). ISO 5208 doesn’t include a backseat test.

Build confidence and pass real audits. In this hands-on course you’ll master:

Start now to cut rework, pass audits, and close dossiers faster.

At NTIA (Norwegian Technical Inspection Academy), we specialize in delivering world-class training programs in vendor inspection, quality surveillance, and technical compliance – specifically tailored for professionals in the oil, gas, and energy industries.

Copyright © 2025 by NTIA. All Rights Reserved.